| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : AMPFORT

Model Number : MZ21-08D112M-102

Certification : ROHS

Place of Origin : Dongguan,Guangdong,China

MOQ : 10000PCS

Price : 0.3 USD/PC

Payment Terms : T/T, Western Union

Supply Ability : 100KKPCS Per month

Delivery Time : 3-4 weeks

Packaging Details : Bulk

Name : Ceramic PTC Thermistor

Voltage - Max : 1.0KV

Resistance - 25°C (Typ) : 1.1kohm

Mounting Type : Through Hole

Package / Case : Radial, Disc

Lead Spacing : 5+/-1mm

Product Marking : SCD 102R

Switching Temp. : 80±10℃

Rated Current : 10mA(25±2℃)

Switching Current : 30mA(25±2℃)

Ceramic PTC Thermistor YS4020 Cross Resettable Fuse 1000V 1100 Ohm 20% Tol For Current Limiting

DESCRIPTION Of The Ceramic PTC Thermistor

PTC THERMISTOR INTENDED FOR USE AS A CURRENT LIMITING PROTECTION DEVICE

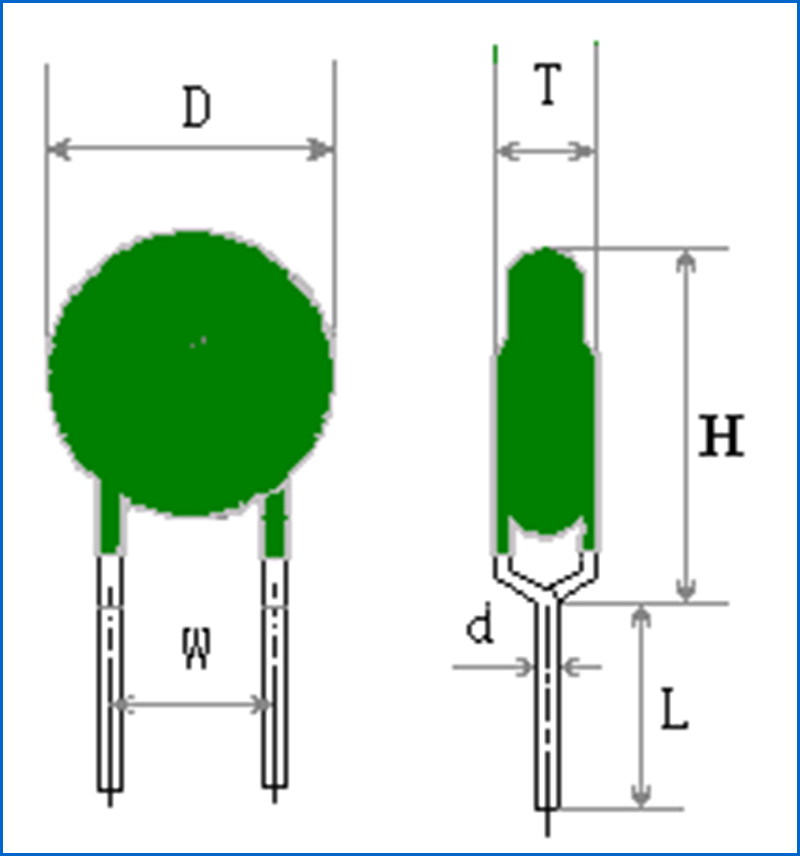

Outline size Of The Ceramic PTC Thermistor

| Model Number | MZ21-08D112M-102 |

| Dmax(mm) | 9.0 |

| Tmax(mm) | 6.5 |

| W (mm) | 5±1 |

| d(mm) | 0.6±0.05 |

| L1min(mm) | 10 |

| Hmax (mm) | 13.5 |

| Part Number | MZ21-08D112M-102 |

| Product Marking | SCD 102R |

| Coating Material and Color | Green,Silicone Resin |

| Lead | Tin – plated copper wire / Short lead / Side-bend |

Electrical Characteristics (Ta =25℃) Of The Ceramic PTC Thermistor

| Part Number | MZ21-08D112M-102 |

| Rated Resistance Rn (Ω) | 1100±20% |

| Switching Temp. Tc(℃) | 80±10 |

| Withstand voltage Up(V) | ≥1000 |

| Rated Current In(mA) | 10(25±2℃) |

| Switching Current It(mA) | 30(25±2℃) |

| Residual Current Ir(mA) | ≤2 |

| Voltage Surge V(V) | 1000 |

Test item and conditions Of The Ceramic PTC Thermistor

| NO | Test Item | Test Condition | Requirements |

| 1 | Appearance Overall Dimension Rated zero power resistance | No visual damage,Pin no oxidation, no broken;Mark shall be complete, clear and identifiable. Measure by vernier caliper. Room Temperature:25±2℃;Place period:≥30min | Fig.1

Table 1 Table 2 |

| 2 | Switching Temperture | Curie temperature is corresponding value at 2 times of R25 R-T curve. | Table 2 |

| 3 | Withstand voltage | At 25±2℃ ambient environment,voltage 220V,last for 3S ;suddenly changed to 1000V, last 30S then cut off power . | 1000 Visual appearance no visible damage |

| 4 | Non-Operating Current | Place in 25±2℃ still air for 30min, power voltage:220VAC,applying with 30mA current,last 1h ,test its resistance change ratio(Test voltage between two PTC lead with voltmeter ,test PTC current with amperemeter ,then can get resistance of PTC). | 10mA(25±2℃) ┃ Resistance change rate ┃≤50% Inaction for 1 hour |

| 5 | Action Current

| After placed in 25±2℃ still air for 30min , power voltage:220VAC,applying with 60Ma current, should go into high-impedance-state in 5 mins. | 30mA Action time ≤5min |

| 6 | Residual current | At 25±2℃ ambient environment,adjust voltage withstand tester to 1000V gradually , steady 10s get reading -current go through PTC,it is residual curent. | ≤2mA |

| 7 | Solderability | Use method of slotted weld ,stain with scaling powder , dip into 230±5℃ lead free tin(Sn96.5Ag3Cu0.5)molten solder groove along the axis direction, last for 3S~5S,body is 5mm far away with molten solder , take out and observe. | The terminals shall be uniformly tinned, and its area≥95% |

| 8 | Resistance to soldering Heat | Use method of slotted weld ,stain with scaling powder , dip into 260±5℃ lead free tin(Sn96.5Ag3Cu0.5)molten solder groove along the axis direction ,last for 3±1S,body is 2mm far away with molten solder,after place in room temperature for 24hours,check appearance and test zero power resistance then compare with initial resistance. | No visible mechanical damage. ┃Resistance change rate┃≤ 20% |

| 9 | High temperature discontinuous load | According to GB7153 1081th experiment,temp 60±2℃,voltage 265V,initial current 400mA,power on 90min,outage 30min,after total load 1000 hours , place in room temperature for 24hours,check appearance and test zero power resistance then compare with initial resistance. | No visible mechanical damage. ┃Resistance change rate┃≤ 30% |

| 10 | Strength of lead terminal | Do experiment according to GB2423-29 test U , test Ua, tension 10N and keep 10s ; test Ub , bend 90°,tension 5N,consecutive 2 times ;test Uc , turn around 180° ,consecutive 2 times ; Place in room temperature for 24 hours,test zero power resistance and compare with initial resistance. | ┃Resistance change rate┃≤ 20% |

|

|

Ceramic PTC Thermistor YS4020 Cross Resettable 1000V 1100 Ohm 20% Tol For Current Limiting Images |